Motors and Feedback (encoders)

by David Kohanbash on December 31, 2013

Hi all

There are many types of motors and feedback methods to choose from. Which do you need? Keep reading to find out more about selecting your motor stackup. Since most field robots are DC powered I am skipping the many types of AC motors that are out there.

In addition to this post you can find out all about how to size your motors and gearboxes and how to control these motors in the linked posts.

Motors

Remember when you are selecting motors that current is proportional to torque, and speed is proportional to voltage.

Many times you will find a motor with the correct torque and rated for some high speed. But if you are running it from some low voltage robot you will get a lower maximum speed.

In another blog post I will discuss gearing which can be used to modify the output torque/speed from you motor stackup. Many of the vendors below will also sell you gearboxes so that you have a complete solution.

Here are a couple of vendors that I have used:

Allied Motion

Danaher Motion – They have most of the motor types above

Futaba – Good source of RC Servos

Kollmorgen – They have most of the motor types above

Maxon Motors – Large selection of small DC motors

Feedback

Having position feedback that can also be used for velocity/speed control) is important for precise motion as well as for using position for dead reckoning your current position. For brushless motors you will also want feedback in order to get better commutation (ie. spin better and gain efficiency). There are back EMF methods for commutating a brushless motor but for good sinusoidal commutation you want the feedback.

In many position systems you might want to have two feedback methods. A primary one for the motor shaft, and an auxiliary one on the final output. This can give you excellent precision and removed mechanical slop from the desired position. The reason for two encoders is that you can use the primary one for velocity commands/control and the auxiliary one for the position commands.

Brakes

Another item that you can often get in your stackup is a brake. A motor brake is useful to prevent back-driving and to hold the last motor position (usually even if the robot gets powered down). Just remember most brakes are designed to be engaged when the motor is not moving. They are NOT designed to stop the motor or reduce its speed. Also watch out on some motors you can not have an encoder and break at the same time.

With all of these options you can often buy them on your own and assemble the full motor stack, however it is often easier and more reliable to have the motor manufacturer do it.

There are some good motor and gearing tutorials at MICROMO.

Image Credits

Brushed Motor – http://www.robotroom.com/Counter/MaxonMotor.jpg

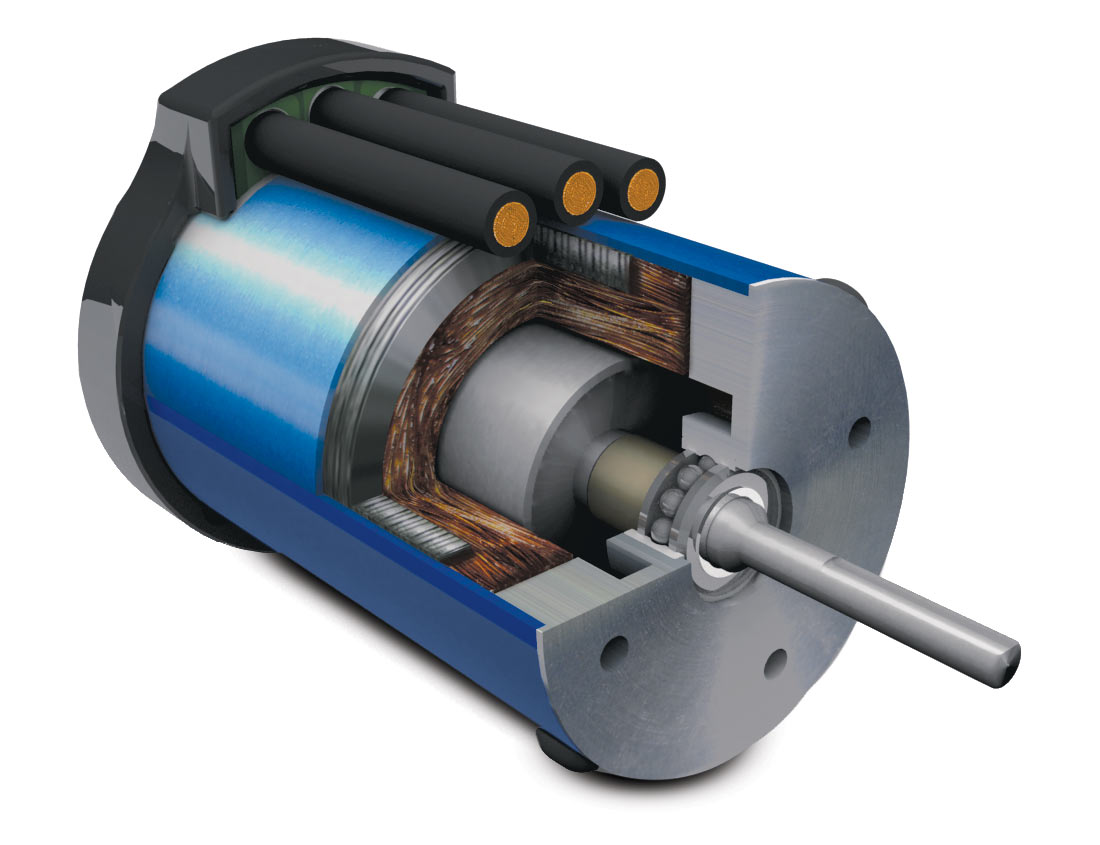

Brushless Motor – http://www.elitektm.com/wp-content/uploads/2011/11/3351_velineon_3500_motor-cutaway.jpg

RC Servo – http://www.redrc.net/wp-content/uploads/2009/06/futababls151.jpg

Linear Actuator – http://www.servocity.com/assets/images/SD_Linear_Actuator_Side_View.jpg

Solenoid – http://mohacks.com/wp-content/uploads/2011/09/tubular-solenoid-L.jpg

Stepper motor – http://upload.wikimedia.org/wikipedia/commons/8/83/Nema_17_Stepper_Motor.jpg

Pancake motor – http://www.extremetech.com/wp-content/uploads/2013/06/HAYDONSWITCH-PLANETARY-PANCAKE-MOTOR-PLANETARY-PANCAKE-MOTOR.jpg

Component Set – http://www.alliedmotion.com/Products/Series.aspx?s=54

Quadrature Encoder – http://frontrangerobotics.org/Jan05/EncoderForRML.jpg

Resolver – http://www.nidec-avtron.com/encoders/images/knowledge-base/resolver1_small.jpg

String Pot – http://www.mmcompsys.com/uploads/mediacentre/20100816011621-String%20potentiometer.jpg

Absolute Encoder – http://www.parkermotion.com/dmxreadyv2/blogmanager/app_engine/assets/images/encoder-rot-large.jpg

Comments

[…] all I recently wrote a post on different types of motors and feedback options, now I want to talk about how to control those motors. Each motor is often refereed to an […]

[…] obtaining this information is from encoders, resolvers (fancy encoders) and potentiometers. See the Motor & Feedback Tutorial for more […]

[…] all Selecting a motor is a critical task when designing a robot. In a prior post we discussed the different types of motors and feedback options as well as how to control those motors. In this post we will focus on how to size your motor and […]

Is there a pancake motor that would fit inside of a circular device with dimensions: 3.35(85mm) x 2.36(60mm) ???????????????

Hi

I do not know off hand. You can try calling some of the vendors. There are links to several motor vendors at https://robotsforroboticists.com/links/ I think Maxon has some pretty small flat motors. But it will all depend on your torque requirement and budget.

You might be able to get a component set so you can “build” the motor your self. This will often save volume but increases the difficulty of assembly and requires tight manufacturing tolerances. I have seem many people mess up with component sets.

[…] Motors & Feedback: https://robotsforroboticists.com/motor-types/ […]